At namuk, there's one golden rule: a piece of clothing only makes it into our collection when it has passed the ultimate stress test. And we don't just mean lab equipment that pulls seams apart or endlessly rubs fabrics. We also mean our mole crew – a handful of fearless little outdoor adventurers who run, crawl, climb, slide, and play in our prototypes … all while being brutally honest.

Only when a piece survives the wild reality of the playground, the walk to school, and the mountain trail is it ready for its next step: years of adventures – and maybe even a second or third life. In our "Behind the Product" series, we’re taking you behind the scenes. Anna and Chiara from the namuk Product Team give you a look at how we test our clothing and how your feedback plays a role in our development process.

Our mole crew – Who actually tests our clothing?

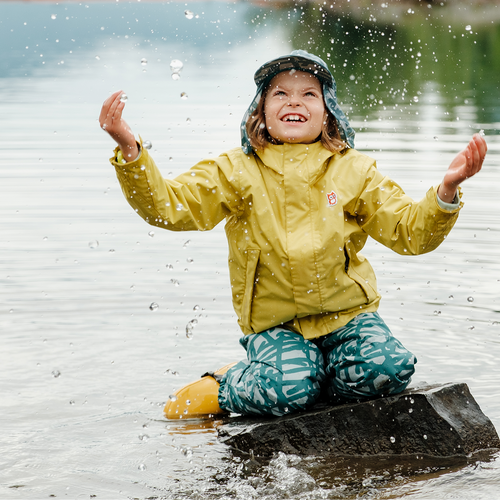

Our mole crew is made up of families who take being outside as seriously as others take their taxes. Some spend their summers on a mountain alp or in an alpine hut (such as the family from the Cluozza Hut, see pictures), others live on a farm, and still others spend their winters on skis and snowshoe tours. And then there are the "everyday heroes" who turn the school run or the playground into a testing ground.

Sometimes, a piece is tested in parallel: one is sent to a truly wild adventurer, and another to a family whose kids wear it in their daily outdoor life. "That's exactly the mix we want – it shows us how a piece performs during constant action versus regular use," Chiara explains.

The briefing is simple: Do what you always do. Wash the clothes when they're dirty. Put them on when it's wet, cold, muddy, or dusty. Play, jump, and slide. We don't want a perfectly preserved sample back – we want it to look like it's lived a whole childhood. "It's important to us that the tests are as close to real life as possible."

The namuk pieces are used in a variety of places: on the alp, for climbing and playing, on snowshoe tours, or while skiing and sledding. But they also have to hold up in the garden, on the way to school, or at the playground. "Asphalt roads in winter without snow are a real challenge – the fabrics rub directly against the rough surface with every step," Anna adds. These everyday situations show us how truly robust a piece of clothing is.

One family even wears the products for ice climbing. Such "extreme adventurers" are a stroke of luck for namuk: they use the clothes much more often than usual. "This way, we can already see after just a few months how a piece would fare over one or two years of adventures," says Chiara.

From adventure to feedback – How we gather input

For our mole crew, the adventure doesn't end with wearing the gear – afterward, the storytelling begins. Each family fills out a detailed feedback form, covering everything from fit and washability to specific details like zippers and elastics. Sometimes we check in after three months, sometimes later – it just depends on when we need answers. "We don't just want to know if something broke, but also how comfortable it was, whether the kids could put it on and take it off themselves, and what we could do even better," Chiara explains.

When it comes to important decisions, we actively seek out this feedback, then sit down as a team to consider which changes can be implemented immediately and which ones can wait.

Lab adventures – How we put fabrics to the test indoors

Of course, we don't just test outside. Indoors, in the lab, machines are waiting to rub fabrics over rough surfaces until they give in, to pull and yank until a weave breaks, and to play sunlight for weeks to see if colors will stay true or fade. "We check for colorfastness against light, washing, friction, sweat, and saltwater," says Anna. All our clothes are tested for abrasion, tear, pilling, and snagging resistance. "These are key indicators for the longevity of our fabrics – and that's what's important to us in every piece of clothing," Chiara adds. The lab also checks if our fabrics are burst-resistant, hold their shape, dry quickly, remain breathable – and, of course, if they are waterproof.

It sounds technical – and it is – but at its core, it's about something very simple: we want to be sure that a fabric doesn't just look good in the lab, but also delivers on its promises outside. That's why with us, what has already passed the outdoor test often goes to the lab after the fact. "A perfect test report is useless to us if the sample is worn out after one season on the playground," Chiara says.

When tests lead to new ideas

Sometimes our tests lead to ideas for entirely new products. "When we tested the fabric for the Linn Shorts, we gave the mole crew a long version of it – simply because the knees are the most stressed area and should be tested accordingly," Chiara recalls. "The pants were so well-received and held up so well that they inspired us to create a new style." (Look out for the upcoming summer collection!)

And sometimes, tests are the starting point for permanent improvements. Softer elastics, more kid-friendly closures, shifted seams for less wear – we don't change things just for the sake of change. If the team decides on a modification, it's because it’s a change that will truly last.

One example that's especially close to the Product Team's heart is the Quest ski suit. "For the 2025 winter collection, we completely revised the cut after receiving various feedback," Anna says. More freedom of movement, no more snow in the boots – achieved through months of fitting sessions with kids in all different sizes. "It was a multi-round process," Chiara remembers. Also the cut was revised by the pattern maker. "In general, the cut and fit are one of the most challenging things in development – especially for kids," Anna adds. "But now the ski suit fits so well that we'll be keeping the change for several seasons."

The outdoors decides, not the lab

And then there are the cases where "perfect on paper" just isn't enough. We were working on a biodegradable version of one of our fabrics and had test samples produced. The initial feedback from the mole crew was generally positive. But as soon as the first samples came back from the families, a different picture emerged: the fabric felt rougher, the texture was less pleasant on the skin, and visually it couldn't compete with the existing version.

We sent a second round of improved fabric samples from the producer out into the field – but the result still didn't fully convince us. On top of that, the minimum production quantity was very high. In the end, we had to make the difficult decision to abandon the project. "We used the fabric in the field twice, both times with feedback," Chiara says. "But if the feel and look aren't right and the fabric already fails with our test families, it's not for namuk."

That's why our rule is: it's better to send three fabric variants out in parallel to see which one truly holds up – and only the winner makes it to the lab and then – if everything checks out – into the collection.

Conclusion: Clothing that loves adventure

In the end, all the testing is about something very simple: making clothing that keeps up with kids. That’s why since 2025, we've been consistently using PFC-free fabrics, offering UPF 50+ sun protection without any added coating, and reinforcing pants with tough Cordura. A piece with the "namuk" label isn't meant to be a short-term guest in the closet – it’s a loyal companion for countless adventures. And if it were up to us, for multiple childhoods.